Introduction:

The diesel fuel pump plays a crucial role in the efficient operation of diesel engines. It is primarily responsible for delivering the appropriate amount of fuel at the appropriate time and under the correct pressure to the combustion chamber. Nevertheless, diesel fuel pump failures can lead to a number of problems, including a decrease in engine performance, an increase in fuel consumption, and the need for costly repairs. We will discuss in this article the top causes of diesel fuel pump failure and provide preventive measures to help you avoid them.

1. Contaminated Fuel:

As one of the leading causes of diesel fuel pump failure, contaminated fuel is of particular concern. Diesel fuel becomes contaminated with dirt, water, and other impurities, causing damage to the fuel pump and injectors. As a means of preventing this, it is imperative to use high-quality, clean diesel fuel and periodically replace fuel filters. Installing a fuel water separator can also help remove water and impurities from fuel before it reaches the engine.

2. Lack of Lubrication:

Fuel pumps in diesel vehicles require lubrication to operate smoothly. Running them without adequate lubrication can cause premature wear and failure. To prevent excessive friction and wear on pump components, ensure that your engine’s oil and fuel system are well maintained and that you use the appropriate lubricants.

3. Overheating:

Diesel fuel pump components can expand when exposed to excessive heat, resulting in leaks and reduced efficiency of the pump. Make sure that your engine’s cooling system is functioning correctly and that your engine is operating within the instructed temperature range to prevent overheating. A proper ventilation system and heat shields can also contribute to the protection of the fuel pump from overheating.

4. Low Fuel Pressure:

Fuel pumps for diesel engines require a specific amount of fuel pressure in order to operate properly. Low fuel pressure can be the result of a clogged fuel filter, a weak fuel pump, or a malfunctioning pressure regulator. Maintain a regular schedule for inspecting and replacing fuel filters, as well as checking the fuel pressure periodically to ensure it meets manufacturer standards.

5. Fuel Additives:

Using inappropriate or low-quality fuel additives can result in fuel pump failure. Additives may contain corrosive chemicals that can damage the pump and other components of the fuel system. Make sure you use reputable fuel additives and follow the manufacturer’s recommendations.

6. Air Intrusion:

The entry of air into the fuel system can cause cavitation and aeration, which might damage the diesel fuel pump. Be sure to inspect all fuel lines, fittings, and connections on a regular basis for leaks. Seal any leaks properly to prevent air from entering the system. Additionally, it is essential to properly bleed the fuel system after any maintenance or component replacement.

7. Injector Problems:

A faulty fuel injector can cause additional stress to the diesel fuel pump. Clogged, worn, or inaccurately calibrated injectors will increase the pump’s workload and cause it to wear out prematurely. Maintaining and calibrating injectors on a regular basis is essential to preventing this issue.

8. Contaminated Fuel Tanks:

Fuel tanks that accumulate debris, rust, or sludge can introduce contaminants into the fuel system, failing the pump. Regularly inspect and clean the fuel tank, and consider adding a fuel tank cleaning or polishing system to ensure that the fuel is of high quality.

9. Improper Storage:

When the engine or vehicle is left unused for an extended period, diesel fuel pumps can become damaged. Fuel can degrade over time, resulting in clogs and corrosion in the fuel system. In order to prevent this, you should store your vehicle in a full tank with fresh diesel fuel and add a fuel stabilizer if you will be keeping your vehicle for an extended period.

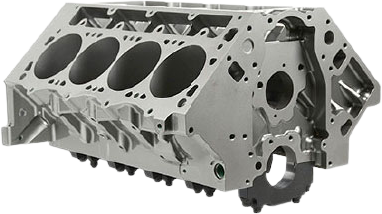

Cylinder Blocks

We are able to test and repair all sizes, makes and models of cylinder blocks. Our services include:

- Complete inspection

- Crack testing and repairing

- Cylinder boring and sleeving

- Counter boring and inserting and more!

Cylinder Heads

Here at ARA, we oer all facets of cylinder head reconditioning services, including:

- Chemical cleaning

- Crack testing

- Grinding

- Pressure testing and more!

Dynamic Balancing

We provide precision balance for petrol and diesel engines. Components we are able to balance include:

- Crankshafts

- Pistons

- Conrods

- Flywheels and more!

Conclusion:

Our Diesel Fuel Pump service at ARA Engine Reconditioning helps you maintain your diesel engine’s performance and longevity by preventing diesel fuel pump failure. Fuel pump failure can be prevented with regular maintenance, clean fuel, proper storage, and handling. Maintaining your diesel engine can keep it running smoothly for years to come.

CONTACT ARA ENGINE TODAY

Get In Touch

Sydney's Leading Engine Reconditioning Service Provider since 1985

Give us a call at (02) 9892 1033 for a quick quote over the phone or to arrange a tow truck if your vehicle is stranded and requires pick-up.

If you prefer to reach out via email, drop us a line at info@araenginereconditioning.com.au, and we’ll get back to you as soon as possible.

Visit us at our workshop, located at 32 Whitaker Street, Yennora, NSW, 2161. Our team is ready to address your engine reconditioning needs and answer any questions you may have.

Business Hours:

We’re open from 8am to 5pm from Monday to Friday and from 8am to 1pm on Saturdays. Feel free to drop by or give us a call during those hours, and we’ll be happy to assist you the best we can.