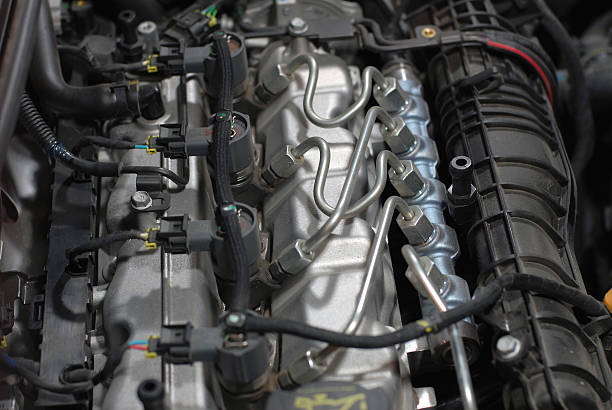

The life of machinery is not without its wear and tear. Over time, as machines are subjected to extensive use, they may become inefficient and require maintenance or repair. Line boring is a significant technique that plays a vital role in restoring such machines’ efficiency. Industries can significantly enhance machine performance and prolong their lifespan by comprehending the essence of line boring services.

The Essence of Line Boring

At its core, line boring is a method of reconditioning worn-out holes and bores in machinery. This process becomes essential when the holes are enlarged, misaligned, or not perfectly round anymore. Rather than replacing an entire machine or component, line boring restores the machine’s alignment, ensuring it runs smoothly.

When is Line Boring Needed?

Misalignment Issues: Prolonged use of machinery can lead to misalignment issues. For rotating equipment, alignment is critical to ensure smooth functioning and prevent premature wear.

Wear and Tear: Over time, with continuous use, the bores in machinery can become worn out. This is especially common in machines with moving parts that are in constant friction with each other.

Equipment Upgrades: Sometimes, when machines are upgraded or modified, their original holes and bores might not be suitable anymore. Line boring is then used to modify these parts to fit the new components.

Benefits of Line Boring Services

Cost-Effective Solution

One of the main advantages of line boring is that it is a cost-effective solution. Instead of replacing an entire machine or a significant component, line boring allows industries to fix the specific problem area. This not only saves money on purchasing new equipment but also on the downtime that would be needed to install and set up a new machine.

Enhancing Machine Lifespan

By regularly maintaining and restoring machines through line boring, industries can prolong the lifespan of their machinery. A well-maintained machine can function efficiently for years beyond its expected life.

Precision and Accuracy

The techniques and equipment used in-line boring are designed to offer high precision. When done by professionals, the result is a machine that operates at its optimal level, with all its components perfectly aligned.

Reduced Downtime

Machines that could be operating more efficiently can lead to longer production times and increased downtime. The machinery can be restored to its optimal condition with line boring services, ensuring smoother operations and reduced downtime.

Environmental Benefits

By reconditioning and extending the life of machinery, industries can reduce waste. Instead of disposing of old machines and components, they can be restored and reused. This not only reduces waste but also the environmental impact associated with manufacturing new machines.

Servicing Sydneys Engines for over 35 Years

Welcome to ARA Engine Reconditioning, the premier provider of engine reconditioning services in Sydney, Australia.

Established in 1986, we have built a reputation as the most trusted and reliable provider in the industry. Our skilled

technicians and state-of-the-art facility allow us to work with a wide range of engines and deliver high-quality results

every time.

Quality Assurance

With up to 5 years warranty

Competitive Rates

Best prices, without the compromise on quality

Convenient Locations

Servicing all areas Sydney-wide

Hands of Knowledge

Trust in the hands with 35+ years experience

Tips for Choosing Line Boring Services

Experience Matters: Choosing a line-boring service provider with extensive experience is essential. A seasoned provider will have encountered various challenges and know how to address them efficiently.

Check for Reviews: Before opting for a special service, checking studies and testimonials is a good practice. This can give you an understanding of the quality of service you can anticipate.

Ask About Equipment: The quality of equipment used in the line tedious process plays a significant role in the final result. Ensure that the service provider uses modern and high-quality equipment.

Get a Quote: Before finalizing a service, get a quote to ensure that the service is within your budget and offers value for money.

CONTACT ARA ENGINE TODAY

Get In Touch

Sydney's Leading Engine Reconditioning Service Provider since 1985

Give us a call at (02) 9892 1033 for a quick quote over the phone or to arrange a tow truck if your vehicle is stranded and requires pick-up.

If you prefer to reach out via email, drop us a line at info@araenginereconditioning.com.au, and we’ll get back to you as soon as possible.

Visit us at our workshop, located at 32 Whitaker Street, Yennora, NSW, 2161. Our team is ready to address your engine reconditioning needs and answer any questions you may have.

Business Hours:

We’re open from 8am to 5pm from Monday to Friday and from 8am to 1pm on Saturdays. Feel free to drop by or give us a call during those hours, and we’ll be happy to assist you the best we can.